Bricks have been a cornerstone in the world of construction for centuries, with their history tracing back to 7,000 BC in Turkey. T

This blog looks at the step-by-step process of brick making, from the initial excavation of clay to the final delivery of these essential building blocks to builders and merchants across the UK.

We explore each stage in detail, revealing the art and science behind one of the most common and essential materials in modern construction.

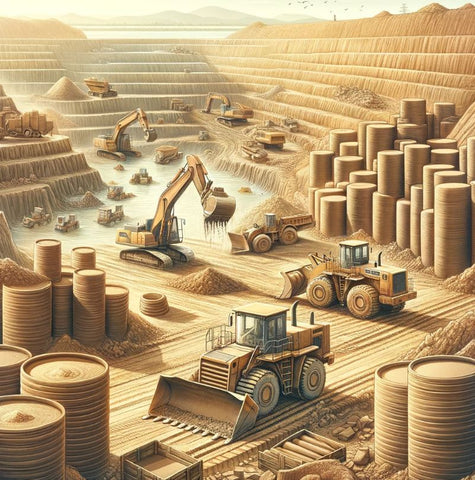

The Beginnings: Clay Excavation and Stockpiling

The journey of a brick begins beneath our feet, with the extraction of clay, a material found in abundance in natural quarries, particularly on floodplains and riverbanks.

- Extraction: Clay is meticulously excavated from these quarries using sophisticated machinery.

- Stockpiling: Different types of clay are then carefully stockpiled, often in layers, to ensure a balanced composition for the final product.

Clay's unique property of becoming moldable when wet and extremely hard when fired makes it an ideal raw material for brick making, a process that humans have mastered over millennia.

Key Takeaway 💡: The careful selection and stockpiling of clay is a crucial first step in brick making, setting the foundation for the quality and consistency of the bricks.

Preparing the Clay: The Foundation of Quality Bricks

Before clay can be shaped into bricks, it undergoes a crucial preparation phase:

- Transportation: The raw clay is moved from the stockpile to the production facility.

- Processing: Here, the clay is ground and milled to achieve a consistent size and shape.

- Additives: Water, sand, and other additives are mixed in to enhance the clay's properties, and colour pigments can be added for aesthetic purposes.

This preparation stage is essential in ensuring the clay is in the optimal state for brick formation, ensuring quality and strength in the final product.

Key Takeaway 💡: The preparation of clay, involving grinding, milling, and mixing with additives, is pivotal in determining the overall quality of the finished bricks.

Shaping the Clay into Bricks: Crafting the Building Blocks

The shaping of bricks, a critical stage in the brick-making process, is where art meets technology, blending traditional craftsmanship with modern industrial techniques. This stage transforms the prepared clay into the familiar brick shape, ready for drying and firing.

Extruded Bricks:

- Process: The extrusion method involves passing clay through a vacuum chamber to remove air bubbles and then forcing it through an extrusion die.

- Formation: This creates a continuous, long column of clay, which is then sliced by wires into individual bricks of consistent size and shape.

- Advantages: The extrusion process allows for high production efficiency and uniformity in brick size, making it a preferred method for large-scale manufacturing.

- Types of Bricks Produced: Extruded bricks are typically more dense and have a smooth surface, often used in both structural and non-structural applications.

Soft Mud Bricks:

- Traditional Approach: This method is one of the oldest and uses softer, more water-enriched clay.

- Moulding: The clay is either pressed or thrown by hand into individual molds, giving each brick a unique texture and appearance.

- Labor Intensive: While more labor-intensive than extrusion, this method is cherished for its artisanal quality and the character it imparts to the bricks.

- Applications: Soft mud bricks are often preferred in restoration work and in buildings where a traditional, handcrafted aesthetic is desired.

Both methods showcase the versatility and adaptability of brick-making to meet various architectural and construction needs. The choice between extruded and soft mud bricks often comes down to the specific requirements of the project, such as structural integrity, aesthetic considerations, and budget constraints.

Drying the Bricks: Preparing for the Kiln

Post-shaping, bricks enter a critical drying phase.

- Stacking and Transport: Shaped bricks are carefully stacked and transported to drying facilities.

- Moisture Reduction: Here, they undergo a controlled drying process, reducing moisture content to below 2%.

This stage is essential in preparing the bricks for the intense heat of the kiln, ensuring they don't crack or warp.

Key Takeaway 💡: Proper drying of bricks is key to preparing them for the firing process, ensuring they retain their shape and integrity.

The Firing Process: Creating Strength and Durability

The firing process is where bricks gain their renowned durability and strength.

- Kiln Firing: Bricks are heated in large industrial kilns at temperatures between 1000 to 1100 degrees Celsius.

- Monitoring: The temperature increase rate and kiln atmosphere are meticulously controlled to ensure consistent quality.

This process imbues bricks with their essential qualities: durability, strength, and fire resistance.

Key Takeaway 💡: The firing process is critical in ensuring bricks possess the necessary strength and durability for construction purposes.

Packaging and Delivery: From Factory to Construction Site

Once fired, bricks are almost ready to be part of construction projects.

- Quality Inspection: Each brick undergoes a stringent quality check.

- Packaging and Distribution: Passing bricks are then packed and distributed to various merchants and construction sites across the UK.

This final stage ensures that only the best quality bricks make it to the building sites.

Beyond the Production Line: Environmental Responsibility

Brick production isn't just about creating building materials; it also encompasses a commitment to environmental sustainability.

- Quarry Restoration: Post-extraction, quarries are often restored to natural habitats to support wildlife.

- Biodiversity Management: Many brick production sites contribute to biodiversity, with areas listed as Sites of Special Scientific Interest (SSSI).

This aspect of brick production shows the industry's commitment to environmental stewardship.

Key Takeaway 💡: The brick industry's efforts in ecological sustainability and biodiversity management demonstrate a responsible approach to production that goes beyond just making bricks.

Conclusion

From clay extraction to the final delivery, the process of making bricks is an intricate blend of art and science. Each stage, from preparing the clay to shaping, drying, firing, and even packaging, plays a vital role in ensuring that the bricks we use in construction are of the highest quality. This journey of brick making not only underscores the craftsmanship involved but also highlights the industry's commitment to environmental sustainability.

Next time you see a brick structure, remember the meticulous process behind each brick. Whether you are a builder, architect, or simply someone interested in construction, we invite you to appreciate the art and science of brick making that builds the world around us.

FAQs

-

What is the primary raw material used for making bricks?

-

Learn about clay, the fundamental raw material in brick-making, including its extraction and preparation process.

-

-

How does the brick shaping process differ between extruded and soft mud bricks?

- Understand the distinct techniques used in the extrusion method and the traditional soft mud approach for shaping bricks.

- Understand the distinct techniques used in the extrusion method and the traditional soft mud approach for shaping bricks.

-

What are the environmental considerations in brick manufacturing?

- Explore how brick manufacturers address environmental concerns, including quarry restoration and biodiversity management.

- Explore how brick manufacturers address environmental concerns, including quarry restoration and biodiversity management.

-

Can the color of bricks be altered during manufacturing?

- Discover how color pigments and additives are used in the clay preparation stage to change the final color of bricks.

- Discover how color pigments and additives are used in the clay preparation stage to change the final color of bricks.

-

Why is the drying process important in brick making?

- Understand the significance of drying bricks before firing and how it affects their quality and durability.

- Understand the significance of drying bricks before firing and how it affects their quality and durability.

-

What temperatures are used in the firing process of bricks?

- Delve into the kiln firing process and learn about the temperature ranges that give bricks their strength and durability.

- Delve into the kiln firing process and learn about the temperature ranges that give bricks their strength and durability.

-

How are bricks inspected for quality before delivery?

- Learn about the quality inspection process that bricks undergo before being packaged and delivered.

- Learn about the quality inspection process that bricks undergo before being packaged and delivered.

-

What makes clay an ideal material for brick making?

- Discover the unique properties of clay, such as its plasticity when wet and durability when fired, making it suitable for brick making.

- Discover the unique properties of clay, such as its plasticity when wet and durability when fired, making it suitable for brick making.

-

How do brick manufacturers ensure consistent quality in their products?

- Explore the measures and controls in place during the brick-making process to maintain a consistent quality in the final product.

- Explore the measures and controls in place during the brick-making process to maintain a consistent quality in the final product.

-

Are there sustainable practices in brick manufacturing?

- Find out about the sustainable practices adopted by brick manufacturers, including the use of recycled materials and energy-efficient processes.